TPU film features and advantages

10-05, 2023

|

10-05, 2023

|

View:

View:

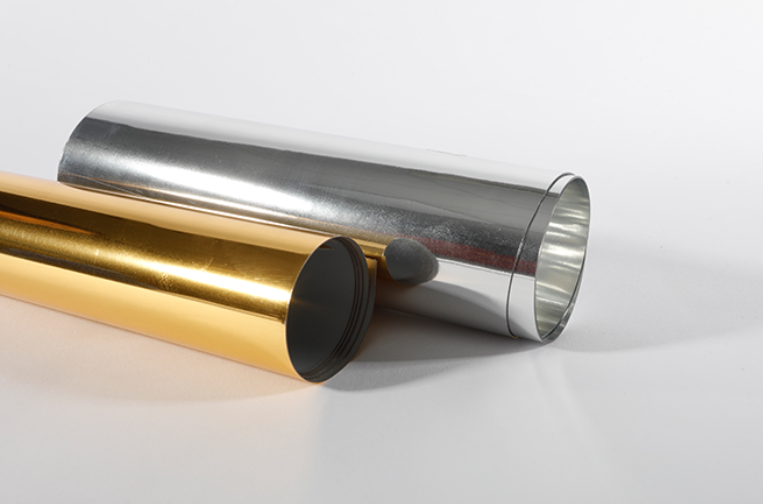

TPU film is a film made on the basis of TPU granules through special processes such as calendering, casting, film blowing, and coating. The thickness is 0.01 to 2mm.

TPU (thermoplastic polyurethane) is becoming increasingly popular due to its superior performance and environmentally friendly concept. Wherever PVC is used, TPU can become a substitute for PVC. However, the advantages of TPU are beyond the reach of PVC. TPU not only has excellent high tensile strength, high tensile strength, toughness and aging resistance, but also is a mature environmentally friendly material.

1. Hardness

The higher the hardness level of the TPU film, the higher the puncture resistance and wear resistance of the product. The hardness level is low, and the product exhibits a very smooth texture and a very soft feel.

2. Wear resistance

TPU films outperform many other common polymers in abrasion resistance. It is more than five times more wear-resistant than natural rubber and is one of the preferred materials for wear-resistant products.

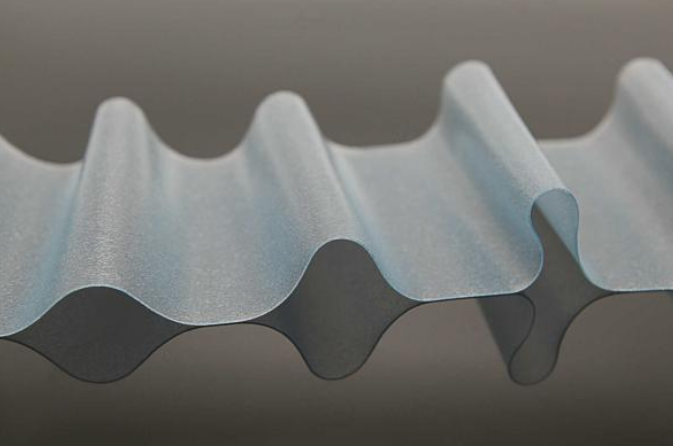

3. Tensile performance

The tensile strength of TPU film is as high as 70MPa, and the elongation at break can be as high as 800%. One of the most commendable properties is its tensile ability.

4. Weather resistance

The weathering resistance of TPU film is better than that of natural rubber and other synthetic rubbers.

5. Low temperature flexibility

TPU film has excellent low temperature flexibility. Most films remain flexible even when exposed to temperatures as low as -30 degrees Celsius, making them an ideal material for a demanding environment.

6. Good temperature resistance

The temperature resistance of TPU film can reach 130 degrees Celsius, and the temperature resistance of polyether series can reach 90 degrees Celsius.

7. Oil and chemical resistance

TPU is a highly polar polymer material that has very little affinity with non-polar mineral oil and is almost not corroded by fuel oil and mechanical oil. Among them, TPU products are characterized by the oil resistance of the polyester series. Better.

8. Biomedical performance

TPU film has excellent biocompatibility, non-toxic, non-allergic, no local irritation, and non-pyrogenic, so it is widely used in medical, health and other related products as well as sports and protective equipment.

9. Environmentally friendly and degradable

The TPU film will not produce air pollution when burned and can biodegrade in soil within 3-5 years. The polyester series will be completely hydrolyzed after being soaked in water at 50 degrees Celsius for half a year, 70 degrees Celsius for 3 weeks, or 100 degrees Celsius for 3-4 days.

10. Wide applicability

TPU films can be processed using vacuum or heat while still retaining their flexibility and performance. This material can also be welded into irregular shapes.

TPU film has been widely used in: shoe materials, ready-made clothing, inflatable toys, aquatic and underwater sports equipment, medical equipment, fitness equipment, car seat materials, umbrellas, suitcases, leather bags, etc.